Cement Industry CEMA Belt Conveyor Drum Pulley

Basic Information

| Place of Origin: | Qingdao China |

| Brand Name: | TSKY |

| Certification: | ISO, CE, BV, FDA |

| Model Number: | CP001 |

| Minimum Order Quantity: | 1 sets |

| Price: | Negotiable |

| Packaging Details: | pallet, container |

| Delivery Time: | 5-8 working days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union |

| Supply Ability: | 5000 sets/month |

Detail Information

| Material: | Steel, Rubber, PP, PA, PVC | Application: | Cement, Mine, Coal Mining, Quarry, Industry |

| Color: | Customized Colors | Size: | Customized Size, Upon Drawing |

| Type: | Flat Belt, Carrying Roller, Head Drive Pulley, Drive Pulley Roller | Bearing: | NSK, SKF, HRB, Ball Bearing, NTN |

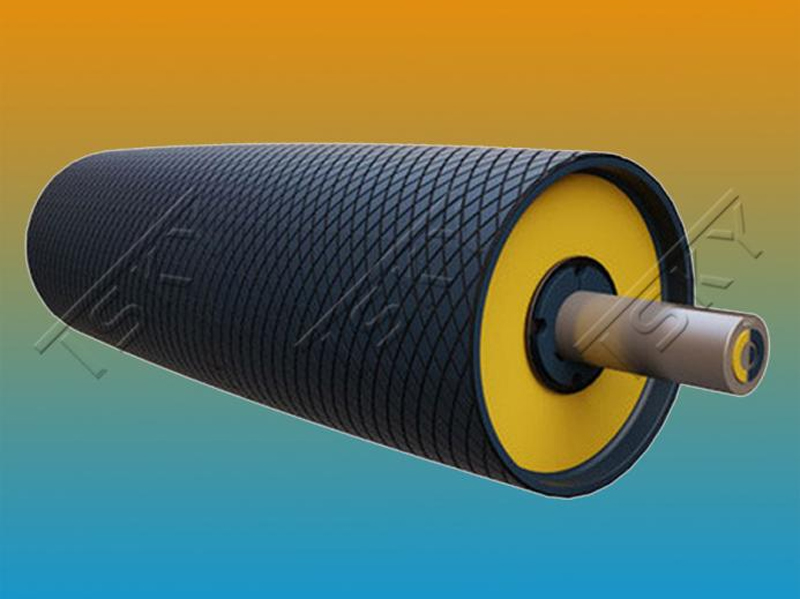

| Condition: | New | Surface Treatment: | Flat, Hot Dip Galvanizing Smooth Steel, Rubber Coat, Herringbone, Rhombic Rubber Lagging |

| Standard: | DIN, JIS, ISO, CEMA, GB | ||

| High Light: |

CEMA Conveyor Drum Pulley, NSK Conveyor Drum Pulley, CEMA belt conveyor drum |

||

Product Description

Belt Conveyor Pulley Drum

Conveyor pulleys play an essential role in the performance and reliability of belt conveyor systems worldwide. Because of this essential role that pulley selection becomes a critical process in keeping equipment up and running. If selection is conducted in haste, a conveyor pulley may be inadequately sized and selected, leading to premature pulley failure and costly downtime.

PULLEY SELECTION

1, The length of the drum choice: different width of the goods should be selected for the width of the drum, under normal circumstances, "transmission + 50mm."

2. The wall thickness and shaft diameter of the drum are selected: According to the weight of the conveyed material, it is evenly distributed to the contacted drum, and the required bearing weight of each drum is calculated to determine the drum wall thickness and shaft diameter.

3, Roller material and surface treatment: According to the different transport environment, determine the drum used materials and surface treatment (carbon steel galvanized, stainless steel, black or covered plastic).

4.Select the installation mode of the roller: According to the specific requirements of the overall conveyor, choose the installation mode of the roller: spring-loaded type, internal shaft type, full-flat type, through pin hole type, etc. For a conical roller of a cornering machine, its roll width and taper depend on the size of the goods and the radius of the turn.

CLASSIFICATION

Drive/Head Pulley – A conveyor pulley used for the purpose of driving a conveyor belt. Typically mounted in external bearings and driven by an external drive source.

Return/Tail Pulley – A conveyor pulley used for the purpose of redirecting a conveyor belt back to the drive pulley. Tail pulleys can utilize internal bearings or can be mounted in external bearings and are typically located at the end of the conveyor bed.

Snub Pulley – A conveyor pulley used to increase belt wrap around a drive pulley, typically for the purpose of improving traction.

Take - Up Pulley– A conveyor pulley used to remove slack and provide tension to a conveyor belt. Take-Up pulleys are more common to conveyors of longer lengths.

Bend Pulley – A conveyor pulley used to redirect the belt and provide belt tension where bends occur in the conveyor system.

SELECTION INSTRUCTIONS

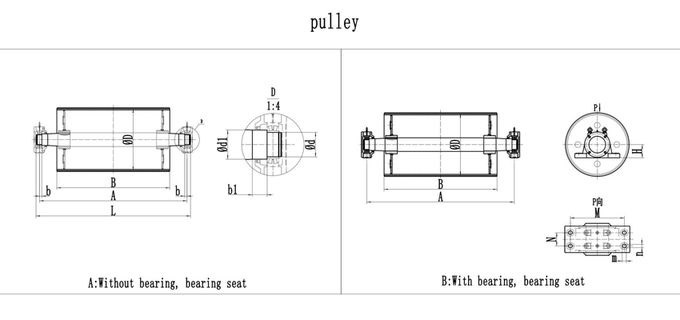

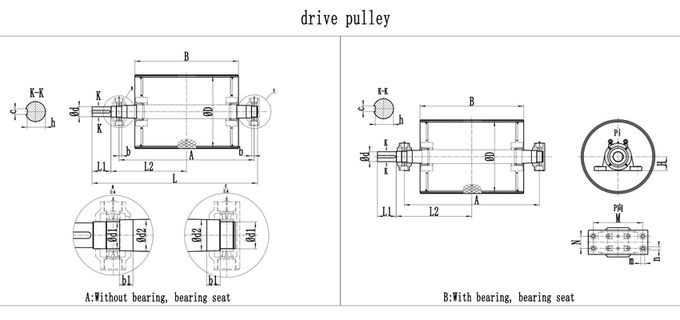

If you need the drive pulley, please refer to the follow picture and fill the size what you need in the tabulation ;

If you need others, such as tail pulley, bend pulley, tension pulley, etc. please refer to the follow pulley picture and give the pulley’s size and requirement you need.