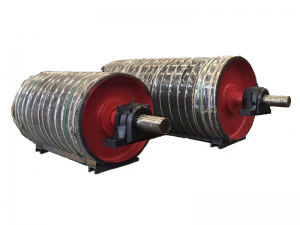

Factory source China Manufacturer Supply Mining Conveyor Belt Drive Pulley Electric Drum Motorized Pulley for Belt Conveyor Electric Conveyor Drum

Our mission would be to grow to be an innovative provider of high-tech digital and communication devices by offering benefit added style, world-class production, and repair capabilities for Factory source China Manufacturer Supply Mining Conveyor Belt Drive Pulley Electric Drum Motorized Pulley for Belt Conveyor Electric Conveyor Drum, Welcome you to join us together to make your business easier. We are always your best partner when you want to have your own business.

Our mission would be to grow to be an innovative provider of high-tech digital and communication devices by offering benefit added style, world-class production, and repair capabilities for China Conveyor Belt Electric Drum and Mining Electric Drum, If you give us a list of merchandise you are interested in, along with makes and models, we can send you quotations. Be sure to email us directly. Our goal is to establish long-term and mutually profitable business relationships with domestic and overseas clients. We look forward to receiving your reply soon.

Overviews

The head pulley is located at the point that the conveyor offloads, known as the unloading end of the belt conveyor. Because it drives the entire system, it usually requires a rough coat covering the outer surface to increase the traction of its belt.

The head pulley usually has the largest diameter of all the pulleys. Sometimes, a system can have more than one pulley as a drive pulley. The discharging end pulley, usually the largest diameter of the driving roller, is called the head pulley.

This is located at the loading end of the belt conveyor. Sometimes it comes with a wing shape to clean the belt by letting material fall aside to the support parts.

In a simple belt conveyor setup, the tail pulley will be mounted on a usually slotted rail to allow belt tensioning. In other belt conveying systems as we shall see, tensioning of the belt is left to another roller called the take-up roller.

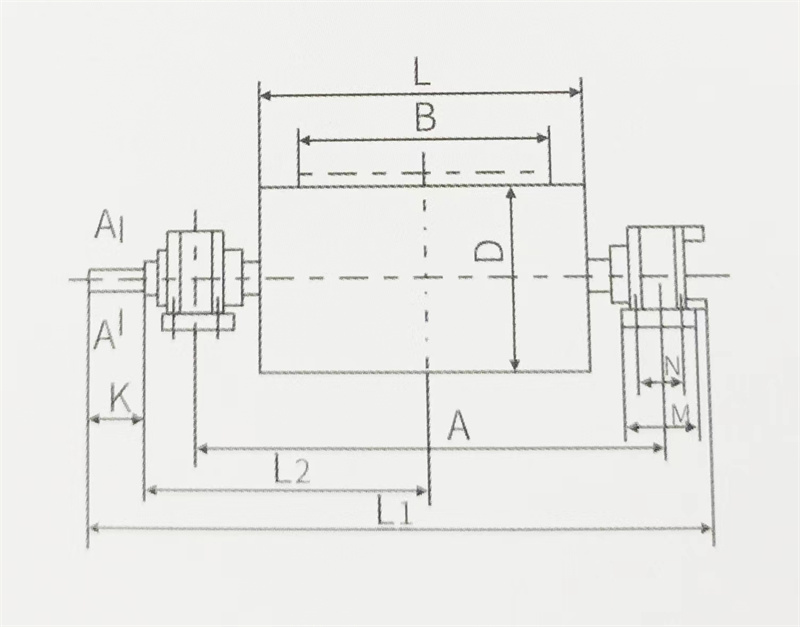

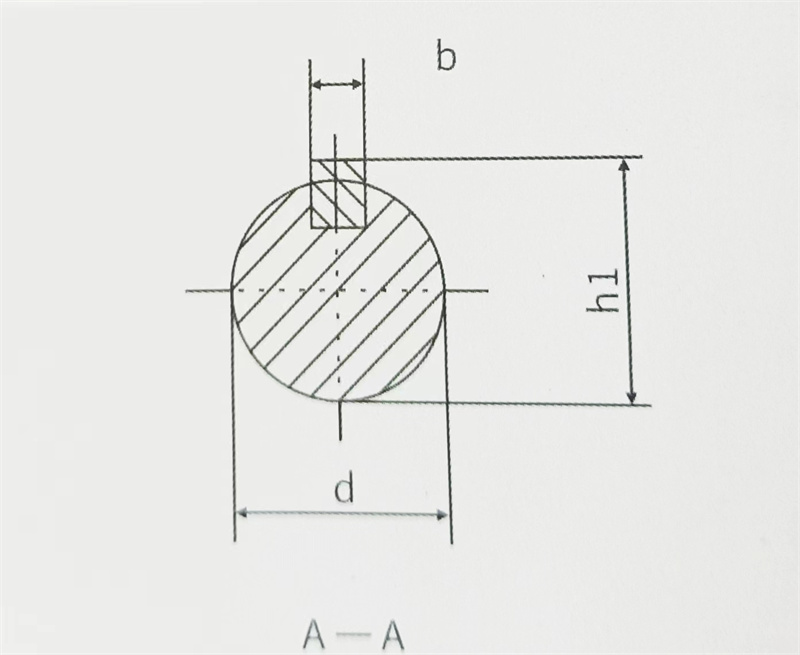

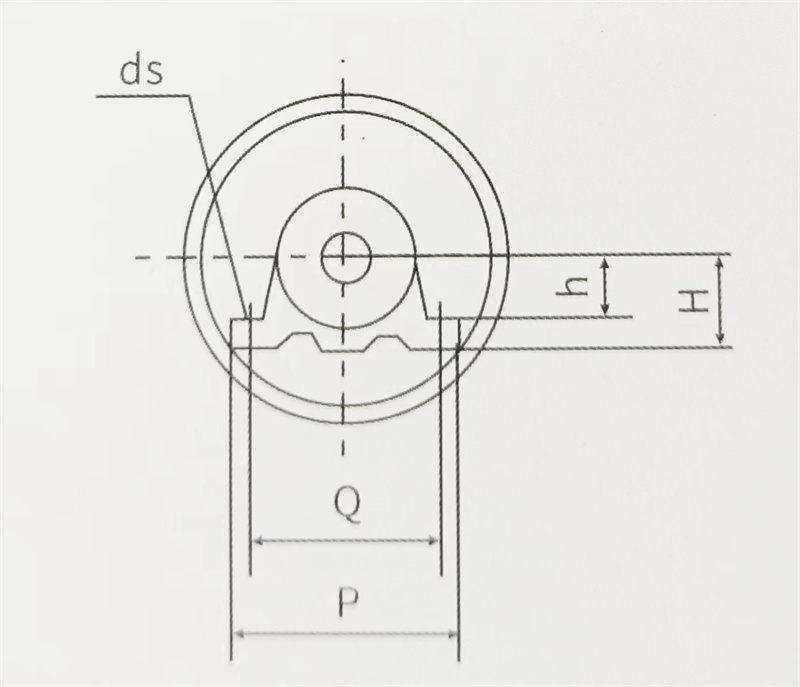

Drive pulley parameters

| B | D | A | L | L1 | L2 | K | M | N | Q | P | H | h | h1 | d | b | ds | Rolling shaft model | Torque allowed(kg*mm) | |

| Smooth surface pulley | Rubber Coated pulley | ||||||||||||||||||

| 500 | 500 | 850 | 600 | 1097 | 505.5 | 115 | 70 | - | 280 | 340 | 33 | 33 | 60 | 55 | 16 | 27 | 1312 | 16300 | 25000 |

| 600 | 500 | 100 | 750 | 1280 | 588.5 | 135 | 90 | - | 350 | 210 | 33 | 33 | 76 | 70 | 20 | 27 | 1316 | 21200 | 32600 |

| 630 | 29600 | 45400 | |||||||||||||||||

| 800 | 500 | 1300 | 950 | 1580 | 738.5 | 135 | 90 | - | 350 | 410 | 33 | 33 | 76 | 70 | 20 | 27 | 1316 | 26200 | 40100 |

| 630 | 1661 | 771 | 175 | 130 | 80 | 380 | 460 | 33 | 33 | 95 | 90 | 25 | 3520 | 36700 | 56100 | ||||

| 800 | 55900 | 85500 | |||||||||||||||||

| 1000 | 630 | 1500 | 1150 | 1861 | 871 | 175 | 130 | 80 | 380 | 460 | 33 | 33 | 95 | 90 | 25 | 27 | 3520 | 45700 | 70100 |

| 800 | 1945 | 900 | 215 | 160 | 90 | 440 | 530 | 53 | 53 | 119 | 110 | 32 | 34 | 3524 | 69600 | 106800 | |||

| 1000 | 2020 | 930 | 255 | 170 | 100 | 480 | 570 | 53 | 53 | 140 | 130 | 36 | 3528 | - | 177500 | ||||

| 1200 | 630 | 1750 | 1400 | 2195 | 1025 | 215 | 160 | 90 | 440 | 530 | 53 | 53 | 119 | 110 | 32 | 34 | 3524 | 54900 | 84000 |

| 800 | 83700 | 128100 | |||||||||||||||||

| 1000 | 2270 | 1055 | 255 | 170 | 100 | 480 | 570 | 53 | 53 | 140 | 130 | 36 | 3528 | - | 213000 | ||||

| 1250 | 2305 | 1065 | 275 | 180 | 110 | 540 | 630 | 53 | 53 | 161 | 150 | 40 | 3532 | - | 300000 | ||||

| 1400 | 800 | 2000 | 1600 | 2445 | 1150 | 215 | 160 | 90 | 440 | 530 | 63 | 63 | 119 | 110 | 32 | 34 | 3524 | 97600 | 149200 |

| 1000 | 2555 | 1190 | 275 | 180 | 110 | 540 | 630 | 63 | 63 | 161 | 150 | 40 | 3532 | - | 249250 | ||||

| 1250 | - | 350000 | |||||||||||||||||

| 1400 | 2635 | 1200 | 335 | 200 | 120 | 590 | 680 | 63 | 63 | 181 | 170 | 40 | 3536 | - | 470000 | ||||

Minimum drum diameter under stable conditions

| Diameter of drive pulley | Minimum diameter | ||||||||

| Maximum tension utilization | |||||||||

| >60%~100% | >30%~60% | ≤30% | |||||||

| Pulley mode | Pulley mode | Pulley mode | |||||||

| A | B | C | A | B | C | A | B | C | |

| 500 | 500 | 400 | 315 | 400 | 315 | 250 | 315 | 315 | 250 |

| 630 | 630 | 500 | 400 | 500 | 400 | 315 | 400 | 400 | 315 |

| 800 | 800 | 630 | 500 | 630 | 500 | 400 | 500 | 500 | 400 |

| 1000 | 1000 | 800 | 630 | 800 | 630 | 500 | 630 | 630 | 500 |

| 1250 | 1250 | 1000 | 800 | 1000 | 800 | 630 | 800 | 800 | 630 |

| 1500 | 1600 | 1250 | 1000 | 1250 | 1000 | 800 | 1000 | 1000 | 800 |

Delivery

Our mission would be to grow to be an innovative provider of high-tech digital and communication devices by offering benefit added style, world-class production, and repair capabilities for Factory source China Manufacturer Supply Mining Conveyor Belt Drive Pulley Electric Drum Motorized Pulley for Belt Conveyor Electric Conveyor Drum, Welcome you to join us together to make your business easier. We are always your best partner when you want to have your own business.

Our mission would be to grow to be an innovative provider of high-tech digital and communication devices by offering benefit added style, world-class production, and repair capabilities for Factory source China Manufacturer Supply Mining Conveyor Belt Drive Pulley Electric Drum Motorized Pulley for Belt Conveyor Electric Conveyor Drum, Welcome you to join us together to make your business easier. We are always your best partner when you want to have your own business.

Factory source China Conveyor Belt Electric Drum and Mining Electric Drum, If you give us a list of merchandise you are interested in, along with makes and models, we can send you quotations. Be sure to email us directly. Our goal is to establish long-term and mutually profitable business relationships with domestic and overseas clients. We look forward to receiving your reply soon.