JIS Standard Rubber Steel Friction Self Aligning Idler

Basic Information

| Place of Origin: | Qingdao China |

| Brand Name: | TSKY |

| Certification: | ISO, CE, BV, FDA |

| Model Number: | TD 75,DTⅡ, DTⅡ A |

| Minimum Order Quantity: | 10 sets |

| Price: | Negotiable |

| Packaging Details: | pallet, container |

| Delivery Time: | 5-8 working days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union |

| Supply Ability: | 5000 sets/month |

Detail Information

| Material: | Rubber, Steel | Standard: | DIN, JIS, ISO, CEMA, GB |

| Size: | Customized Size, Upon Drawing | Condition: | New |

| Application: | Cement, Mine, Coal Mining, Quarry, Industry | Bearing: | NSK, SKF, HRB, Ball Bearing, NTN |

| High Light: | JIS self aligning carrying idler,

CEMA self aligning idler, JIS self aligning idler |

||

Product Description

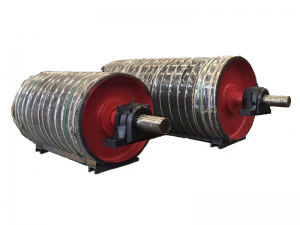

Friction self aligning roller

We are providing an extensive series of Conveyor Idler Rollers to our patrons. This product is made employing the best quality components, attained from skillful dealers of the market. In addition, industry professionals check our presented product in order to deliver top products to our clientele. The product, offered by us to our customers is used in commercial domain for various purposes.

Roller introduction:

The roller is an important part of the belt conveyor. There are many types and large quantities, which can support the weight of the conveyor belt and the material. It accounts for 35% of the total cost of a belt conveyor and generates more than 70% resistance, so the quality of the roller is particularly important.

Working principle of friction self-aligning idler:

Using the friction resistance and friction wheel radian mechanism to prevent and correct the deviation of the conveyor belt to achieve the effect of centering.

Function of friction self-aligning idler:

The role of the roller is to support the weight of the conveyor belt and the material. The operation of the roller must be flexible and reliable. Reducing the friction between the conveyor belt and the rollers plays a key role in the life of the conveyor belt, which accounts for more than 25% of the total cost of the conveyor. Although the roller is a small part in the belt conveyor and the structure is not complicated, it is not easy to manufacture high-quality rollers.

Advantages of friction self-aligning idler:

1. Low rotation resistance, long service life, small maintenance workload and high carrying capacity

2. The different axis degrees of the bearing positions at the two ends of the friction self-aligning roller are less than 0.05 mm, the radial runout of the outer circle is less than 0.3 mm, the rotation resistance is less than 1N, and the mass of the rotating part is reduced by 1/3, which can make the conveyor accessories realize Long haul distance, large capacity, and high-speed operation.

3. The frictional self-aligning roller and the drum bag tape basically realize synchronous operation, with little wear between each other, and extend; the service life of the tape and the driving rubber roller.

Operation of friction self-aligning idler:

1. Before using the roller, carefully check the appearance for any serious bumps and damage. The rotating roller should rotate flexibly without jamming.

2. The installation distance of the rollers should be determined by scientific calculations based on the type of logistics and the characteristics of the conveyor, and avoid excessive or dense installation.

3. The roller installation should be adapted to avoid friction between each other.

Maintenance of friction self-aligning idler:

1. The normal service life of the roller is more than 20000h, and generally does not need maintenance. However, according to the place of use and the size of the load, a corresponding maintenance date should be established, timely cleaning and oil injection maintenance, and timely cleaning of floating coal. The rollers with abnormal noise and non-rotating should be replaced in time.

2. When replacing the bearing, the opening of the bearing cage must be opened outwards. After the bearing is installed into the idler, the proper clearance should be maintained and not crushed.

3. The labyrinth seals should be made of original parts, and should be put into the rollers during assembly, and should not be assembled together.

4. During use, the roller should be strictly prevented from hitting the roller tube by heavy objects.

5. To ensure the sealing performance and use performance of the roller, it is forbidden to disassemble the roller at will.