Motorized Rubber Lagging Head Driving Conveyor Drum Pulley Roller

Basic Information

| Place of Origin: | Qingdao China |

| Brand Name: | TSKY |

| Certification: | ISO, UNI, DIN, AFNOR, FEM, BS, JIS, SANS and CEMA. |

| Model Number: | YTH,TDY75,WD,YZ,DY1,JYD,YDB,YZWB |

| Minimum Order Quantity: | 1 sets |

| Price: | Negotiable |

| Packaging Details: | pallet, container |

| Delivery Time: | 5-8 working days |

| Payment Terms: | L/C, D/A, D/P, T/T, Western Union |

| Supply Ability: | 5000 sets/month |

Detail Information

| Material: | Steel, Rubber | Color: | Customized Colors |

| Type: | Head Drive Pulley | Condition: | New |

| Standard: | ISO, UNI, DIN, AFNOR, FEM, BS, JIS, SANS And CEMA | Application: | Cement, Mine, Coal Mining, Quarry, Industry |

| Size: | Customized Size, Upon Drawing | Bearing: | NSK, SKF, HRB, Ball Bearing, NTN |

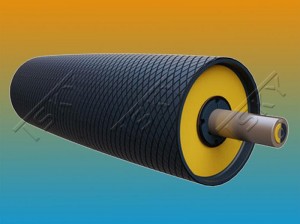

| Surface Treatment: | Hot Dip Galvanizing Smooth Steel, Rubber Coat, Herringbone, Rhombic Rubber Lagging |

Product Description

Motorized Rubber Lagging Head Driving Conveyor Drum Pulley Roller

It is designed to deliver excellent performance, reliability, and longevity in demanding industrial environments.The pulley roller is made of durable rubber and features a lagging head for superior grip and traction, ensuring that the conveyor operates smoothly and without slippage. The motorized design ensures a consistent and powerful movement, driving the conveyor forward with ease.

This pulley roller is easy to install, maintain, and operate. It is an essential component in many industrial applications, such as mining, construction, and manufacturing. Its reliable performance ensures that the conveyor system runs efficiently, reducing downtime and improving productivity.In addition to its excellent functionality, this pulley roller is designed with safety in mind. Its compact design minimizes the risk of accidents and reduces the risk of equipment damage, ensuring the safety of operators and the longevity of the system.In summary, the Motorized Rubber Lagging Head Driving Conveyor Drum Pulley Roller is an essential component in conveyor systems, offering reliable and efficient performance. Its durable construction, superior grip, and easy operation make it ideal for use in a variety of industrial applications.

Motorized Pulley Working Conditions:

1. The operating environment temperature is -15℃, +40℃;

2. The altitude does not exceed 1000 meters;

3. The temperature of the conveyed material does not exceed 60℃;

4. Voltage 380V, frequency 50Hz.

Motorized Pulley Features:

1. It can replace the widely used motor-reducer type external drive device to form a belt conveyor, which can transport bulk materials such as coal, ore, sand, cement, flour, etc., and can also transport finished items such as hemp bales and equipment .

2. The structure is simple and compact, and the space area is small.

3. It is well-sealed, suitable for working places with high dust concentration and damp muddy soil.

4. Easy to use and maintain, safe and reliable operation, and long life.

5. Low energy consumption and easy to realize centralized control.

6. It can meet all kinds of backstop, brake, rubber coating and other requirements.

Standard of Motorized Pulley:

ISO, UNI, DIN, AFNOR, FEM, BS, JIS, SANS and CEMA.

Selection instructions

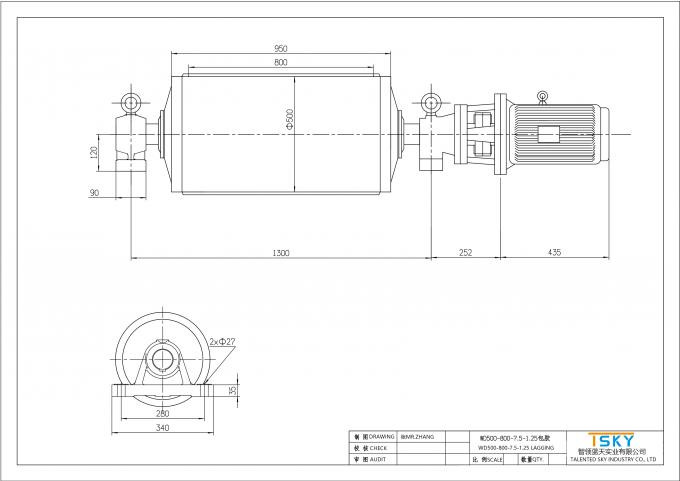

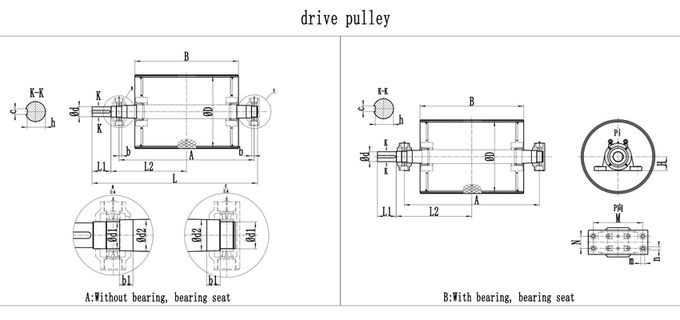

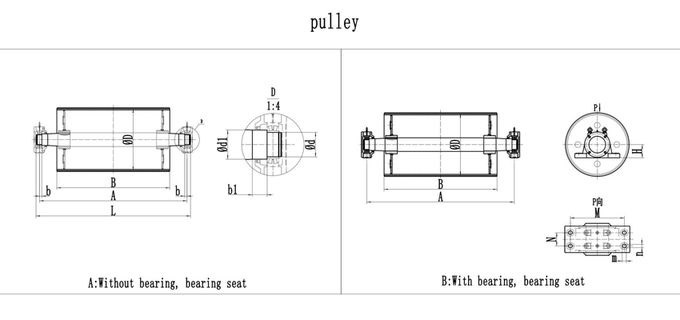

If you need the drive pulley, please refer to the follow picture and fill the size what you need in the tabulation ;

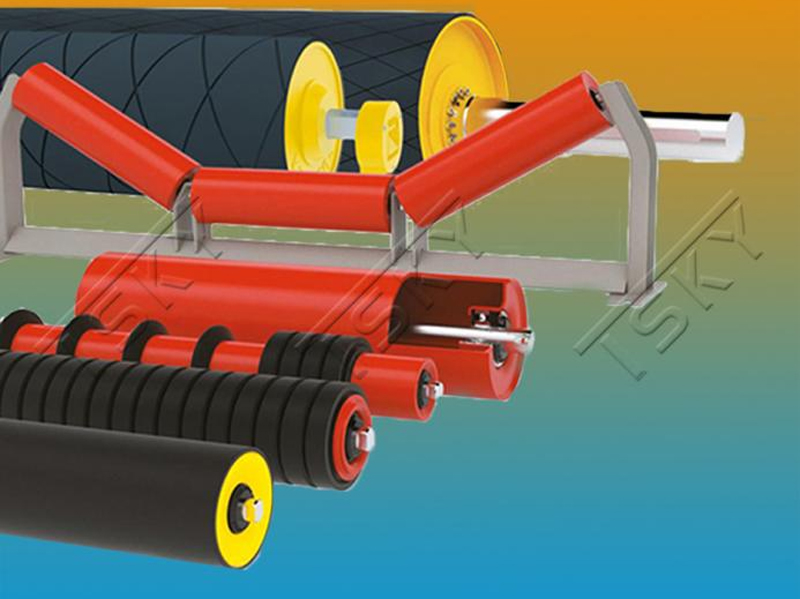

If you need others, such as tail pulley, bend pulley, tension pulley, etc. please refer to the follow pulley picture and give the pulley’s size and requirement you need.

Layout Drawing of Motorized Rubber Lagging Head Driving Conveyor Drum Pulley Roller