Tapered Self Aligning Roller

Basic Information

|

Place of Origin: |

Qingdao China |

|

Brand Name: |

TSKY |

|

Certification: |

ISO, CE, BV, FDA |

|

Model Number: |

TD 75,DTⅡ |

|

Minimum Order Quantity: |

100 sets |

|

Price: |

Negotiable |

|

Packaging Details: |

pallet, container |

|

Delivery Time: |

5-8 working days |

|

Payment Terms: |

L/C, D/A, D/P, T/T, Western Union |

|

Supply Ability: |

5000 sets/month |

Detail Information

|

Material: |

Rubber, Steel |

Standard: |

DIN, JIS, ISO, CEMA, GB |

|

Size: |

Customized Size, Upon Drawing |

Condition: |

New |

|

Application: |

Cement, Mine, Coal Mining, Quarry, Industry |

Bearing: |

NSK, SKF, HRB, Ball Bearing, NTN |

|

High Light: |

Tapered self aligning roller, CEMA Self Aligning Roller, Tapered self aligning idler |

||

Product Description

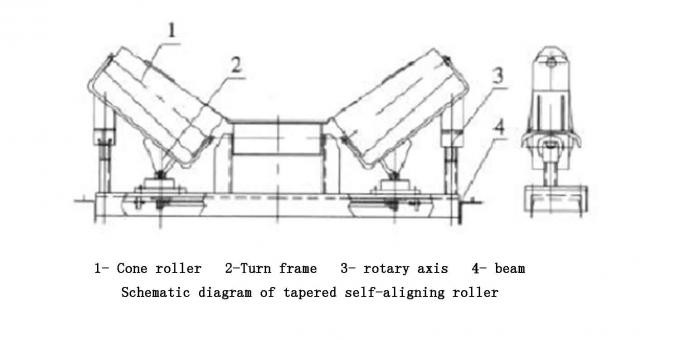

Tapered self-aligning roller

In order to keep pace with never ending demands of the customers, our company is instrumental in offering Self Aligning Idler Roller.

Roller introduction:

The roller is an important part of the belt conveyor. There are many types and large quantities, which can support the weight of the conveyor belt and the material. It accounts for 35% of the total cost of a belt conveyor and generates more than 70% resistance, so the quality of the roller is particularly important.

Working principle of tapered self-aligning roller:

Because the diameter of the two ends of the tapered roller is different, when the roller rotates, the same roller angular velocity produces different linear speeds on the tapered diameter. According to the relationship between angular velocity and linear velocity, when the angular velocity is constant, the linear velocity is proportional to the radius. Therefore, on a tapered roller, the linear velocity of the big end is high and the linear velocity of the small end is low, and there is a linear velocity difference on one roller. When the conveyor belt deviates, the conveyor belt comes into contact with the small end of the roller. Due to the small linear speed, an additional resistance is generated between the roller and the conveyor belt, which drives the slewing frame to rotate a certain angle around the axis of rotation to form a set of supporting rollers. The belt exerts lateral thrust to prompt the belt to return to its original position after the deviation, so as to realize the automatic correction of the deviation belt and ensure the belt running in the center.

The function of the tapered self-aligning roller:

It is used to support the load side of the belt conveyor to adjust the deviation of the conveyor belt to prevent snakes and ensure the stable operation of the conveyor belt.

Features of tapered self-aligning roller:

The trough-shaped roller is replaced with a tapered roller, and the linear speed difference is used to make the roller turret generate a forward tilting force, and the force condition of the roller is changed, so that the lateral thrust generated after the conveyor belt is deflected is increased. The heart effect is more obvious.

Operation of the tapered self-aligning roller:

1. Before using the roller, carefully check the appearance for any serious bumps and damage. The rotating roller should rotate flexibly without jamming.

2. The installation distance of the rollers should be determined by scientific calculations based on the type of logistics and the characteristics of the conveyor, and avoid excessive or dense installation.

3. The roller installation should be adapted to avoid friction between each other.

Maintenance of tapered self-aligning roller;

1. The normal service life of the roller is more than 20000h, and generally does not need maintenance. However, according to the place of use and the size of the load, a corresponding maintenance date should be established, timely cleaning and oil injection maintenance, and timely cleaning of floating coal. The rollers with abnormal noise and non-rotating should be replaced in time.

2. When replacing the bearing, the opening of the bearing cage must be opened outwards. After the bearing is installed in the idler, the proper clearance should be maintained and not crushed.

3. The labyrinth seals should be made of original parts, and should be put into the rollers during assembly, and should not be assembled together.

4. During use, the roller should be strictly prevented from hitting the roller tube by heavy objects.

5. To ensure the sealing performance and use performance of the roller, it is forbidden to disassemble the roller at will.